Table of Contents

In the world of printing and manufacturing, particularly in the realm of high-quality books and packaging, there’s a secret ingredient that can elevate your product from good to great. It’s varnishing. But what exactly is varnishing, and why should you care about it?

Varnishing in printing is akin to the final touch of gloss on a new car – it enhances appearance, durability, and overall quality. It’s a process applied in the final stages of printing to add a protective layer and aesthetic appeal to the printed material.

As the CEO of Huaxin Printing, with 35 years of experience in the industry, I’ve seen firsthand how varnishing can transform a product. It’s not just about making things look pretty; it’s about adding value and ensuring longevity.

What are the major types of varnishing?

Varnishing is a printing process that applies a glossy or matte coating to enhance appearance and durability. Different from lamination which involves a sealed plastic layer, varnishing uses a clear liquid that dries to protect printed materials and give them a polished, professional look. But did you know there are several types of varnishes, each serving a unique purpose? Let’s explore the major types:

Gloss Varnish: This is the go-to for making colors vibrant and images pop. Gloss varnish adds a high sheen, enhancing the depth and richness of the printed colors. It’s perfect for high-impact visual pieces like photo books or advertising materials.

Matte Varnish: For a more subdued, elegant look, matte varnish is the answer. It reduces glare and gives a soft, non-glossy finish. This type of varnish is ideal for products where a sophisticated, understated appearance is desired, such as in art books or luxury packaging.

Satin Varnish: Striking a balance between gloss and matte, satin varnish offers a medium level of sheen. It’s a versatile choice that enhances readability while providing a quality finish, suitable for a wide range of products.

UV Varnish: Known for its durability and resistance to wear, UV varnish is cured under ultraviolet light, creating a hard, protective coating. It’s often used for covers of books or packaging that require extra protection.

Aqueous Coating: A fast-drying, water-based coating, aqueous coatings provide a protective seal over the printed material. They are less likely to yellow over time compared to traditional varnishes and are more environmentally friendly. Aqueous coatings are commonly used for soft-touch and high-gloss finishes in high-quality printing applications.

How is varnishing processed on book and packaging printing?

Varnishing in the printing process is a fascinating and crucial step, enhancing both the durability and the aesthetic appeal of printed materials. Here’s a simplified overview of how varnishing is processed:

Preparation: Before varnishing, the printed materials need to be completely dry. This is essential to ensure that the varnish adheres properly and the underlying ink doesn’t smudge or bleed.

Application: The varnish is applied over the printed surface. This can be done in various ways depending on the type of varnish and the desired effect. For instance, in offset printing, the varnish is often applied using an additional unit in the printing press, similar to how ink is applied. In digital printing, it might be applied as a separate post-print process.

Types of Application:

Flood Varnishing: This involves applying varnish over the entire surface of the printed material, providing uniform protection and sheen.

Spot Varnishing: In contrast, spot varnishing is applied only to specific areas of the print, creating a mix of textures and highlights. This is often used to draw attention to certain elements, like logos or titles. When getting ready for spot varnishing, it’s crucial to carefully set up the design files. Just make sure to clearly mark the areas where you want that special touch. This ensures accuracy and gets you the visual impact you’re aiming for.

Drying and Curing: After application, the varnish needs to dry and cure. The time and method for this vary. For example, UV varnishes are cured quickly under ultraviolet light, while other varnishes might air dry or require heat.

Quality Check: Post-varnishing, a quality check is essential to ensure the finish is even, the desired effect is achieved, and there are no defects.

Varnishing not only protects the printed material but also adds a level of sophistication and quality. It’s a process where precision and attention to detail are key, ensuring that the final product stands out for all the right reasons.

Issues need extra attention when applying varnishing on book printing

When it comes to applying varnishing on book or packaging printing, there are some important things to watch out for:

Even Coverage: Make sure the varnish is applied evenly. This helps in achieving a consistent look and protection.

Drying Time: Give the varnish enough time to dry properly. Rushing can lead to smudges and imperfections.

Spot Varnishing Precision: For spot varnishing, be precise in indicating the areas. Clarity in design files is key.

Quality Checks: After varnishing, do a thorough quality check to catch any issues early on.

Environmental Considerations: Think about the environment. Using eco-friendly varnishes is a responsible choice.

Communication: Keep open communication with your printing partner. Clear instructions and expectations are vital.

Cost Considerations: While varnishing adds value, it also comes with costs. Balance quality with budget.

Timing: Plan varnishing in your production schedule to avoid delays in delivery.

By paying attention to these factors, you can ensure that varnishing enhances the appeal and durability of your printed books and packaging, without any unnecessary hassles.

Can varnishing be applied together with other finishing treatment?

Varnishing can be combined with various other finishing techniques to achieve distinct and eye-catching results in printed materials. Here’s a closer look at some of the finishing treatments that can complement varnishing:

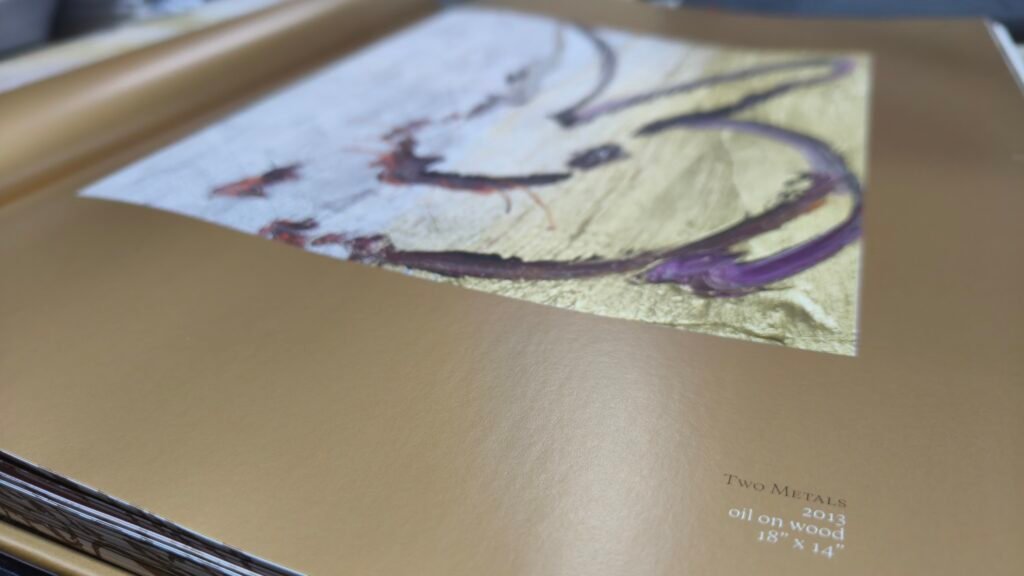

Foil Stamping: This technique involves applying a metallic or colored foil to specific areas of a printed piece. When combined with varnishing, it creates a striking contrast between the glossy varnish and the foil, enhancing visual appeal.

Embossing/Debossing: Embossing raises certain design elements above the surface, creating a tactile effect. Debossing, on the other hand, depresses the design into the material. Pairing these techniques with varnishing adds texture and depth to printed materials, making them more engaging.

Die-Cutting: Die-cutting involves cutting out specific shapes or patterns from printed materials. When combined with varnishing, it can create intriguing designs with glossy or matte finishes, adding a unique touch to promotional materials or packaging.

Texture Coatings: These coatings create textured surfaces, such as sandpaper or leather-like textures. Pairing texture coatings with varnishing can result in materials with both a unique tactile experience and a protective glossy or matte finish.

The key to successful combinations is clear communication with your printing provider. By discussing your objectives and desired effects, they can guide you on the best way to integrate these finishing techniques effectively and achieve the desired impact on your printed materials.

Conclusion

In summary, varnishing is a versatile and valuable technique in printing, offering protection and a better look. Whether you want to make your book covers stronger or your packaging prettier, varnishing can help a lot. It’s like the finishing touch that makes your printed stuff stand out.

At Huaxin Printing, we’ve been using varnishing for over 35 years to make our printed stuff look great. We know how important varnishing is to make things special. Your ideas are important to us, and we’re here to make them look awesome with varnishing.