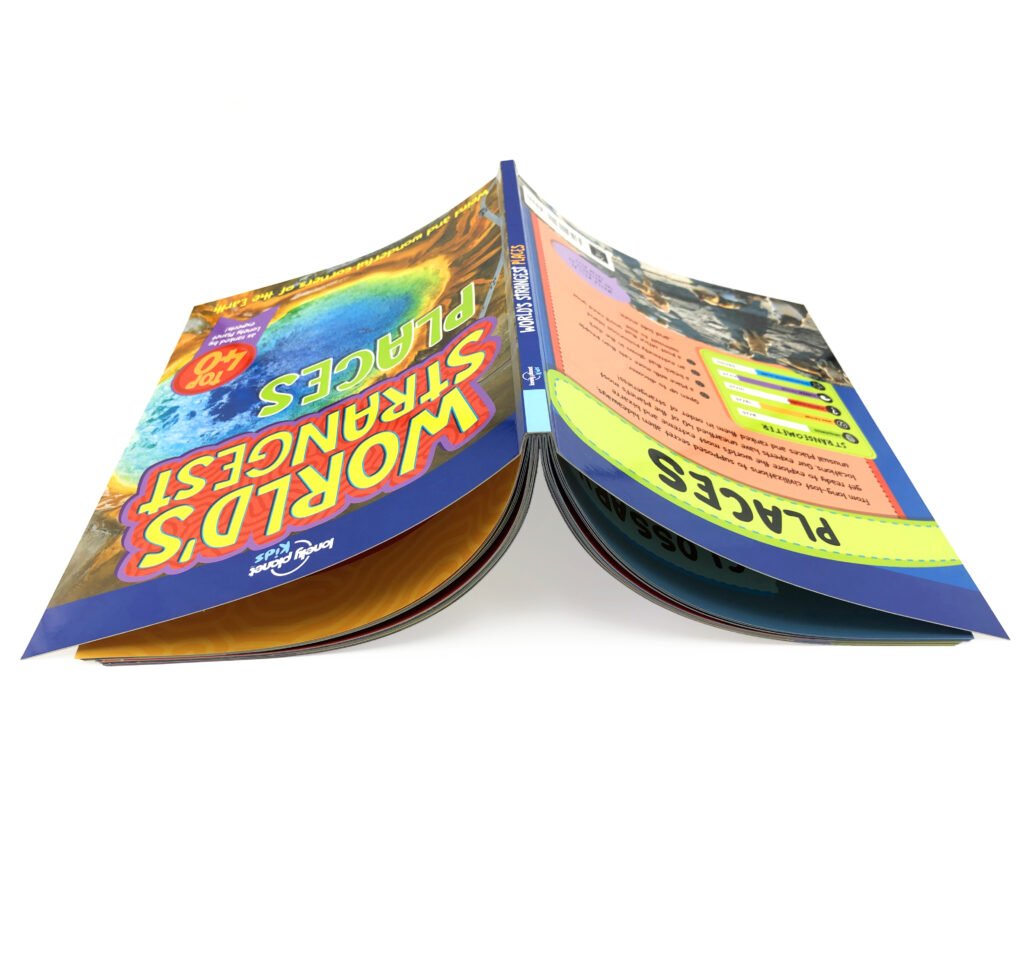

Workflow

The typical procedure of manufacturing a softcover book includes prepress, printing, folding, sewing, casemaking and casebound. Such a complex process requires advanced machinery and seasoned expertise.

With 35 years in the industry, Huaxin Printing offers a one-stop in-house manufacturing solution, eliminating the need for outsourcing. Our specialized color management ensures your product meets the highest standards.

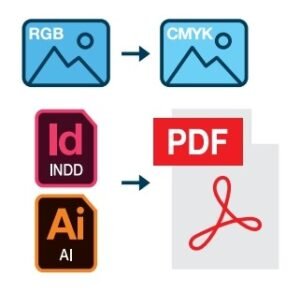

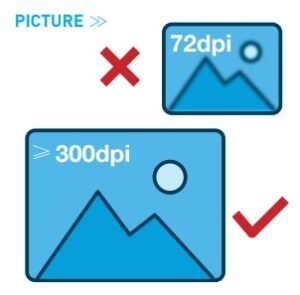

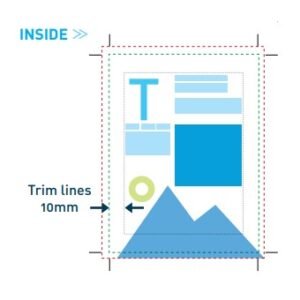

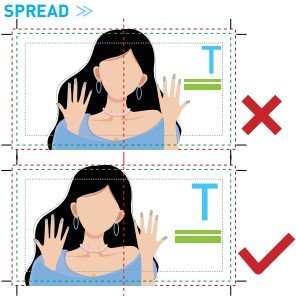

Prepress

Advance prepress equipments and compliance with ISO 12647-7 color management standard. That ensures your files will get accurate proofing before put to print.

Printing

Fully automated printing presses with the speed of up to 18,000 sheets per hour. CIP-3 ink management and experienced press operators.

Folding

Swift adjustment of any trim sizes from 8-page per signature to 64-page per sheet.

Sewing

Fully automated sewing machines ensuring all pages are secured by thread

Binding

Glue the spine and bind the text block with C1S card paper. Capable of completing section sewn, perfect binding and PUR binding

Packing

Professional packaging team makes sure that your products will be safely delivered no matter how far the destination is.